Kunshan ORLLMR Precision Company Ltd is a professional production of the peripheral automation surrounding enterprises. The main products are: three in one feeding machine, stamping manipulator, large slitting machine, punching mesh production line, precision leveling machine and so on.

The structure and function of the metal slitting machine:

1, storage platform: for raw material storage, also known as raw material standby, and generally customize 1-2.

2, the rolling stock: the raw materials stored in the storage table are transported into the coiler and through the functions of ascending, descending and front and back movement, the raw materials are penetrated into the drum, which usually adopts visual / manual methods, and can also be made into a fully automatic "V" plane or roll type plane.

3, open book machine: usually a single cantilever type, such as the large weight of the raw material, need to add auxiliary support to the end of the open reel. The open coil seat usually has the function of moving along the parallel direction of the single machine. It can effectively and quickly complete the raw material pair, generally adopts visual / rear motion, and can also be made into automatic automatic pair, but it needs to be increased. Expensive costs.

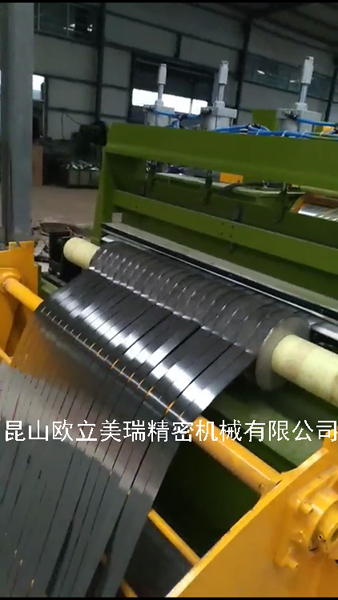

The structure of metal slicing machine is made up of open book (unwinding), material location, bar cutting, coiling and winding. Its main function is to cut the wide coil material in the length direction into a narrow size coil, so as to prepare for other processing procedures in the future.

Metal slitting machine has the advantages of reasonable layout, convenient operation, high automation, high production efficiency and high working precision. It can process all kinds of cold rolling, hot rolled coil, silicon steel plate, stainless steel plate, color plate, aluminum plate and all kinds of metal sheet after electroplating or after coating.

The application of metal slicing machine is widely used in automobile, farm vehicle, container, household appliances, packaging, building materials and other metal sheet processing industry.

The 1.5 meter slicing machine made by Ou Li mi Rui for Henan customers is mainly satisfied with their needs, flexible, convenient and fast, and does not need to wait for materials such as queues. From raw material to finished product one-stop service, save intermediate points, transportation and other links. A large extent ensures that the order is completed on time.